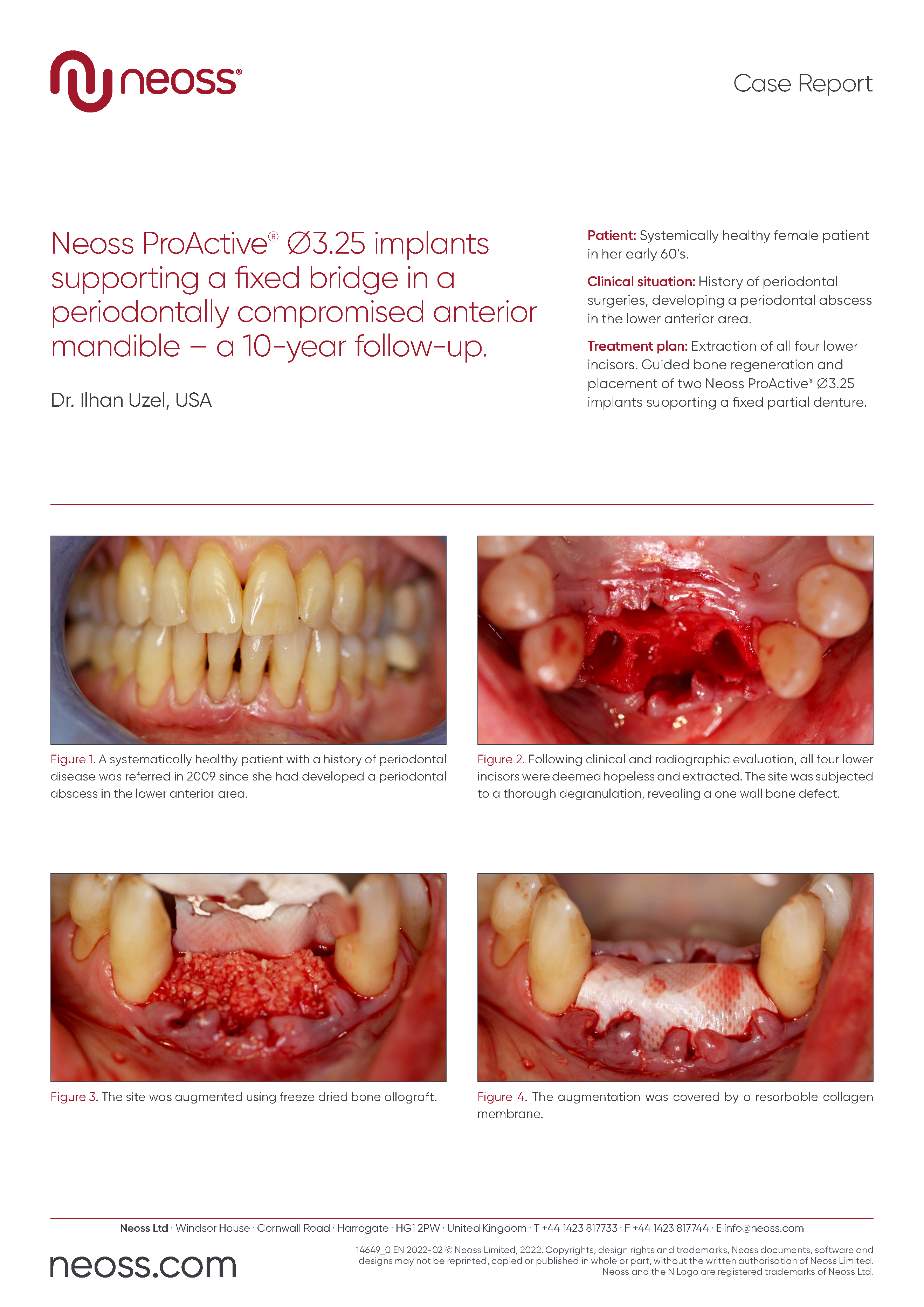

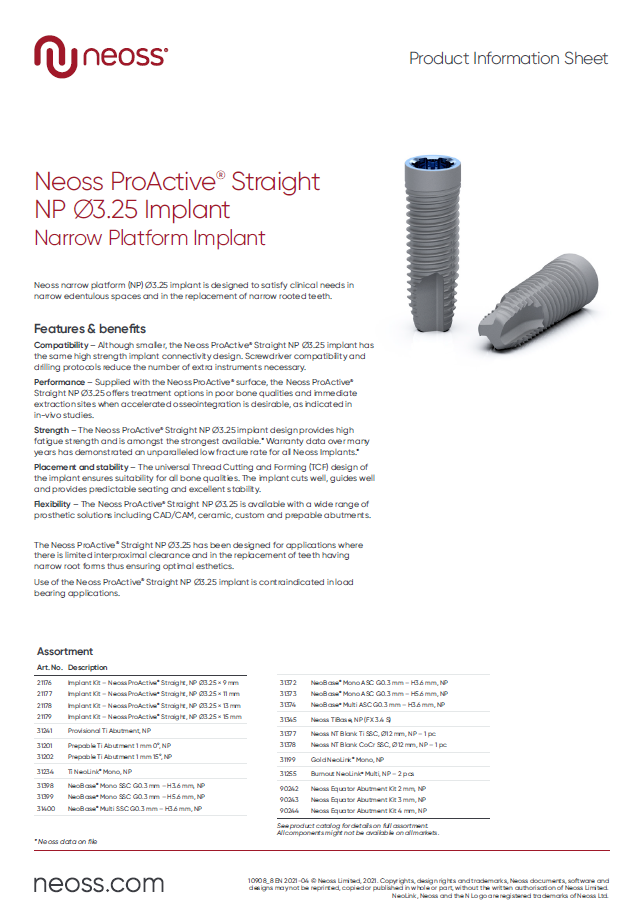

Neoss ProActive® Narrow

The Neoss ProActive Narrow Ø3.25 is one of few Ø3.25mm and smaller diameter implants that is designed for both single teeth and bridges. It delivers excellent primary stability, even in compromised sites, and can be used for Immediate loading after insertion.

Why Neoss ProActive® Narrow

Flexibility

This Narrow Ø3.25mm implant is the only smaller diameter implant that is designed for both single teeth and bridges. It is available with a wide range of prosthetic solutions including CAD/CAM, ceramic, patient individual, and prepable abutments.

Stength

The Neoss ProActive Narrow ∅3.25 implant design provides high fatigue strength and is amongst the strongest available with high fatigue strength values of over 200 N.1 Warranty data over 20+ years has demonstrated an unparalleled low fracture rate for all Neoss implants.1

Compatibility

Although smaller, the Neoss ProActive Narrow ∅3.25 implant has the same high-strength implant connectivity design as all Neoss implants. Screwdriver compatibility and drilling protocols reduce the number of extra instruments necessary.

Placement and stability

The universal Thread Cutting and Forming (TCF) design of the implant ensures suitability for all bone qualities. Thanks to this design, it delivers excellent primary stability, even in compromised sites, and can be used for immediate loading after insertion.

Performance

Supplied with the Neoss ProActive surface, this Narrow ∅3.25 implant offers treatment options in poor bone qualities and immediate extraction sites when accelerated osseointegration is desirable, as indicated in in-vivo studies.

Platform

The Neoss ProActive Narrow implant features a smaller dimensional version of the NeoLoc internal connection with a dedicated and extensive Ø3.25 abutment assortment.

The Neoss ProActive surface

The Neoss ProActive surface has demonstrated faster and stronger osseointegration compared to a blasted implant surface in in-vivo studies.1

The surface is achieved by subjecting the commercially pure titanium implant to a multistage blasting, etching, and super hydrophilicity treatment, which enables the implant to achieve a high level of wettability. As a result, Neoss ProActive Implants have a super hydrophilic surface.

The rougher surface on the threaded implant body stimulates bone to form more rapidly and with greater strength at the implant surface, allowing for earlier loading protocols.

The Neoss ProActive production process and packaging minimizes the already low carbon content on the surface, maximizing surface energy.

Receive the latest news from Neoss, live webinars, new products, and much more!

Neoss ProActive® Narrow

%20(1).jpg)

- Neoss data on file.

- Gottlow J & Sennerby L, 2010. ‘Influence of surface and implant design on stability of five commercial titanium implants. A Biomedical study in the rabbit’, AO Meeting, Post 83

- Renouard F, Nisand D. Short implants in the severely resorbed maxilla: a 2-year retrospective clinical study. Clin Implant Dent Relat Res. 2005;7 Suppl 1:S104–10.

- Meredith N; A review of implant design, geometry and placement. Appl Osseointgrated Res 2008 6 pp 6–12.